以下文章来自二重内部通讯稿:

核电石化公司创新应用全球首台泵壳双钨热丝堆焊技术

The world's first pump casing with TIGer how wire cladding technology--The innovative application of Nuclear power petrochemical company

TIGer: tungsten inert gas electrically reinforced technology, a torch equipped with two electrodes.

主泵是核电厂的心脏,而泵壳是主泵的关键设备之一。华龙一号的安全性和寿命对主泵泵壳设计制造提出了更高要求。

The main pump is the heart of the nuclear power plant, while the pump casing is one of the key equipments for the main pump. The safety and durability of Hualong No. 1 proposes higher requirements on the design and manufacture of the main pump casing.

泵壳内壁堆焊,传统的焊接工艺是借助于外围设备:翻转变位机来实现工件转动,然后将焊接机头悬挂于操作机上,采用焊机接头不动,工件旋转来完成内壁堆焊焊接,但泵壳内壁形状有不规则曲面异常的地方,而且焊接空间受限,此时就需要人进去进行手工焊接,特别是在内壁进行过渡层309L堆焊时为热堆,整个堆-焊过程很长,而且必须保证母材不低于一定预热温度,工作环境及工艺条件十分苛刻,焊接起来非常困难。

The traditional process for the inner wall cladding of the pump casing is with the help of the peripheral equipment: overturn the positioner to realize the rotation of the workpiece; then install the welding head on the column boom and finish the overlaying process by fixing the welding head while rotating the workpiece. However, the shape of the inner wall of the pump casing is irregular and curved, and the welding space is very limited. At this point, manual welding is required. Especially when carrying out the transition layer 309L overlay in the inner layer, it is hot cladding and takes long time. It’s a necessity that the temperature of the base metal is not lower than the certain preheating temperature. The working environment and process conditions are very harsh. All these make it very difficult to weld with traditional welding technology.

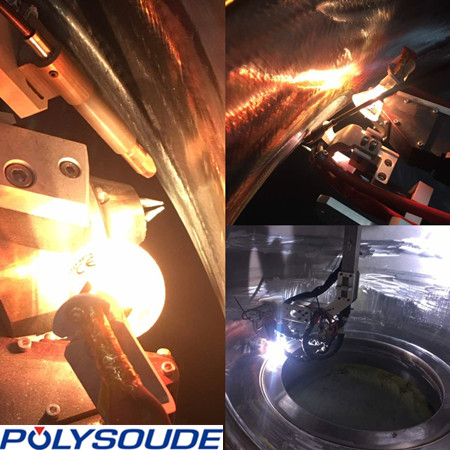

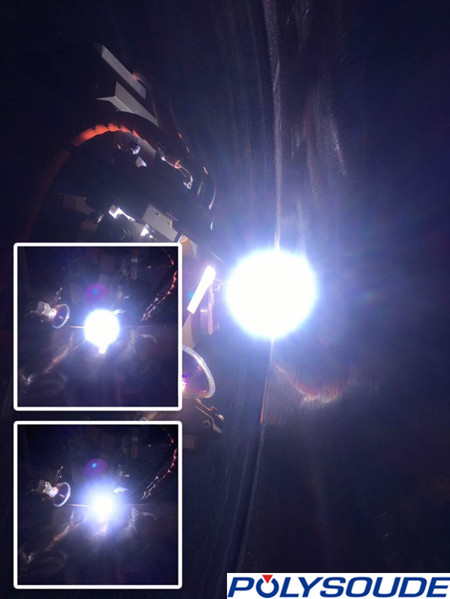

为此,为了改善工人操作环境和劳动强度,确保产品耐蚀层堆焊质量,二重装备核电石化公司技术部引进上海宝利苏迪公司SPX无限回转双钨热丝TIG堆焊操作机,利用SPX无限回转焊接机头(无需考虑线缆缠绕)旋转带动焊枪在泵壳内壁进行圆周焊接。在开始焊接时通过操作机自动定心功能,实现焊接机头旋转中心与工件出入口中心在同一心度上(同心精度在0.1mm内),焊接机头深入泵壳内壁,焊枪具有角度调节机构,焊枪在0-360°角度范围内可进行调整,可实现1G,2G,4G位置的焊接功能。在焊接整过程通过编程设置和AVC实现弧长自动跟踪,有效避免工件不规则,异形相贯线位置不精确引起的钨极或焊丝粘碰工件导致焊接失败,从而满足运行中的各种空间干涉、以及堆焊厚度和宽度以及变径位置的堆焊需求。

To this end, in order to improve the working environment and labor intensity of workers, and to ensure the quality of corrosion-resistant layer surfacing of the products, the technical department of CNEG brings in the POLYSOUDE SPX endless rotating TIGer how wire cladding machine. Without considering the cable winding, the SPX endless rotating welding head keeps rotating which drives the torch to perform circumferential welding on the inner wall of the pump casing. At the beginning of welding, with the automatic centering function of the column boom, we can keep the rotation center of the welding head and the entrance and exit hole center of the workpiece at the same concentricity (the concentric accuracy is controlled within 0.1 mm). The welding head reaches deep into the inner wall of the pump casing, and the torch has an angle adjusting mechanism which allows the torch to be adjusted from 0-360° so as to realize 1G, 2G and 4G welding functions. The whole welding process is programmed and the arc length is automatically controlled, which effectively avoid welding failure caused by tungsten electrode or wire sticking to workpiece due to the irregularities of the workpiece and the inaccurate position of the contoured intersection. That’s why it can satisfy various overlaying requirements i.e. all kinds of space interferences, different cladding thickness and width, and the variable diameter positions.

采用TIG热丝堆焊泵壳内壁的堆焊整个过程使用高纯氩气对焊接热影响区进行完全保护,堆焊后母材和堆覆金属之间的稀释率非常低3%-10%,熔敷生产效率相对于传统焊接2-3倍,堆焊后能够按照工艺要求获得精确的几何形状,返工率低,节约大量时间成本。

By TIG hot wire overlay technology, the welding heat affected area is protected by high purity argon gas during the whole welding process. The dilution ratio between the base metal and the deposited metal after cladding is very low, about 3%-10%. The deposition rate is about 2 to 3 times compared with the traditional welding. After cladding, the precise geometry can be obtained according to the process requirements and the rework rate is low which can save a lot of time and cost.

二重装备核电石化公司这次与宝利苏迪紧密联系,通力合作开发的双钨热丝TIG堆焊机,使我国核电装备国产化制造能力实现了新的跨越,制造技术实现了新的突破,制造水平实现了新的提高。

CNEG works closely with Polysoude this time and jointly develops TIG tungsten hot wire overlay machine which marks a new leap in the localized manufacturing capability, new breakthroughs in manufacturing technology and new improvements in the manufacturing of nuclear power equipment in China.

“华龙一号”是中国核电“走出去”发展战略和推进“一带一路”建设的重要举措,是国家能源发展规划的重要步骤。“华龙一号”核电项目系列产品,让中国核电在“走出去”的历程中,由过去的“借船”出海,“拼船”出海,向“造船”出海转变。通过具有自主知识产权先进核电技术的输出,带动工程、设备、材料、技术服务以及技术标准的全方位“走出去”。

"Hualong No. 1" is an important measure for China's nuclear power "going out" development strategy and promoting the "Belt and Road" construction. It is also an important step in the national energy development plan. In the past, for China’s nuclear power products “going out”, we used to buy directly from other countries or collaborate with them. But now "Hualong No. 1" nuclear power products promote the transforming from traditional ways to making our own products. Through the output of advanced nuclear power technology with independent intellectual property rights, it will drive all aspects “going out” from engineering, equipment, materials, technical services to technical standards.

更多详情欢迎致电咨询:400-092-1088

扫描微信二维码,获取POLYSOUDE更多资讯!